An engine hoist is a tool used for replacing or repairing automotive engines. They are referred to as automotive lifts or cherry pickers. Engine hoists have a sturdy steel or aluminum frame, a boom, and a chain lift. Engine weight can be hundreds or thousands of pounds. Their weight requires a strong hoist to lift and suspend them as they are being repaired. Read More…

At Spanco, Inc., we take pride in designing and manufacturing high-performance lifting solutions that improve efficiency, safety, and productivity across industrial environments. As a leading producer of electric hoists and overhead crane systems, we bring together decades of engineering expertise and precision craftsmanship to create equipment that supports a wide range of material handling...

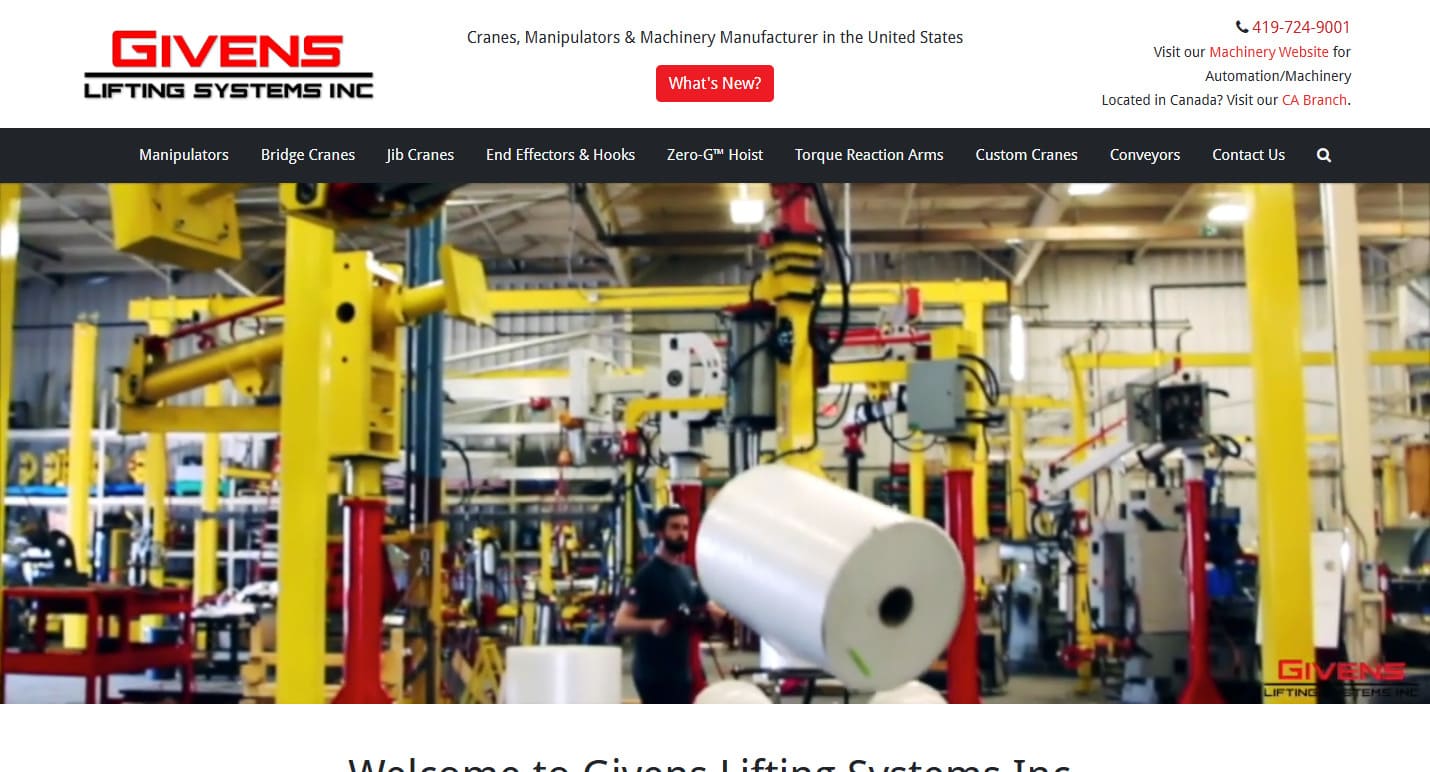

We are Givens Lifting Systems, Inc., a leading company specializing in providing high-quality lifting solutions, with a primary focus on cranes. With our extensive expertise and commitment to innovation, we have established ourselves as a trusted partner for various industries worldwide.

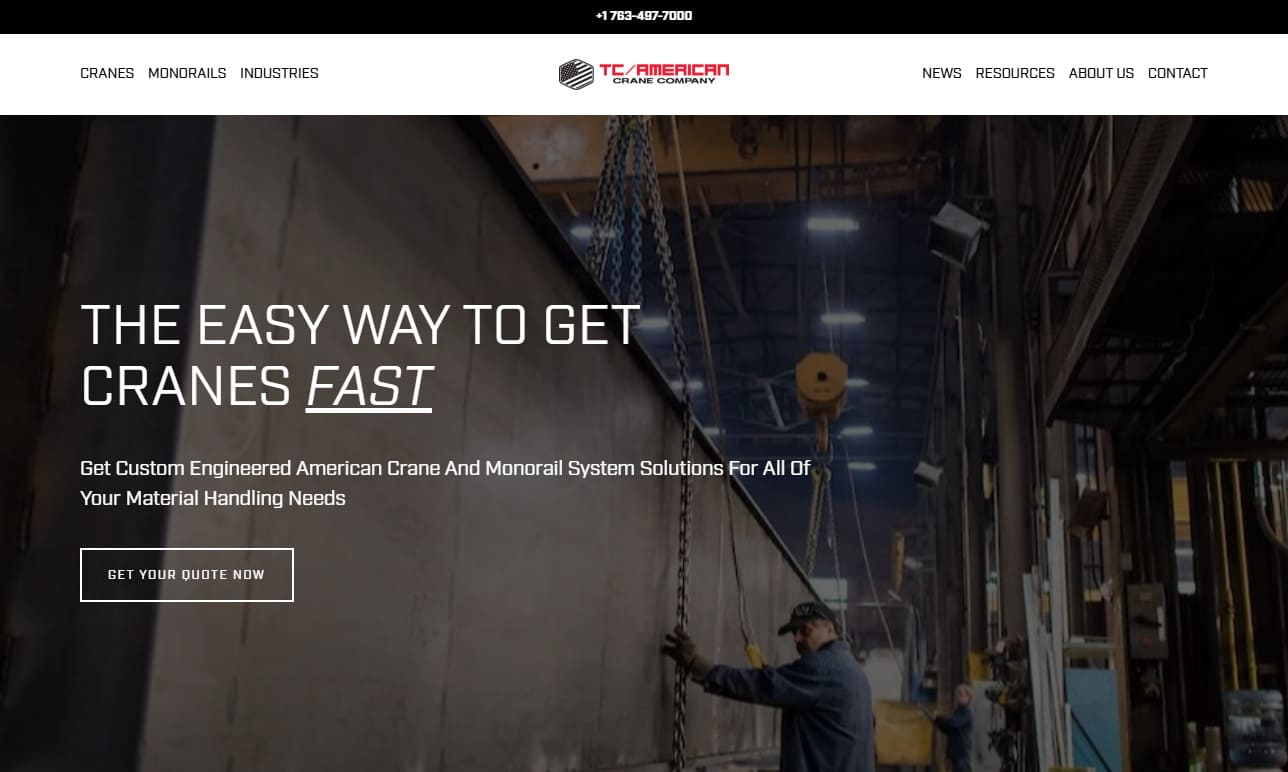

At TC/American Crane Company, we position ourselves as a trusted partner for customers who rely on safe, efficient, and durable lifting solutions. We design and manufacture electric hoists and integrated crane systems that help streamline material handling in demanding environments.

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

More Engine Hoist Manufacturers

Comprehensive Guide to Engine Hoists: Types, Applications, and Buying Tips

Engine hoists, also known as engine cranes, cherry pickers, or engine lifts, are essential lifting devices widely used in automotive repair, manufacturing, shipyards, and industrial environments. Their primary function is to safely lift, move, and position heavy engines or other bulky components. Whether you are a professional mechanic, automotive enthusiast, or industrial operator, understanding the features, benefits, and selection criteria for engine hoists can help you improve efficiency and safety in your workspace.

Engine Hoist Design and Core Components

The design of modern engine hoists includes a robust boom that extends outward from a steel frame, with an attached chain and hook system connecting to the lifting eyes on a motor or other heavy load. The boom is mounted on a frame with an adjustable reach, allowing for flexible positioning and easy access to engines of varying sizes. The frame is supported by two or more legs, which can be fixed, folding, or telescopic—depending on the hoist's capacity and intended use. These features make engine hoists indispensable for removing, installing, or transporting engines in cars, trucks, boats, and industrial equipment.

Are you searching for the best engine hoist for your garage, workshop, or industrial facility? Below, we explore the main types of engine hoists, their mechanisms, advantages, and key considerations for selecting the right model for your needs.

How Does an Engine Hoist Work?

Although traditional, hand-powered, chain-driven hoists are available for DIY engine work, the majority of professional engine hoists are powered by hydraulic cylinders or electric motors that provide the force and power necessary for heavy-duty lifting. Typical hydraulic engine hoists operate much like a hydraulic jack: a handle is inserted into the base of the hydraulic cylinder and pumped to raise or lower the engine. For high-volume or intensive workloads, electric engine hoists offer the convenience of remote or push-button operation, reducing physical strain and improving productivity.

In addition to automotive applications, engine hoists are used in manufacturing, construction, marine repair, and warehouse settings—wherever precise, heavy lifting is required. Their versatility, combined with their robust safety features, makes them a mainstay for professionals and hobbyists alike.

Electric Engine Hoists vs. Hydraulic Engine Hoists

Electric hoists are commonly deployed in factories and warehouses as an alternative to hydraulic engine hoists. Featuring a powerful electric motor, electric hoists eliminate the need for manual operation, offering consistent, reliable lifting at the push of a button. Wired or wireless remote controls provide added precision, making electric engine hoists ideal for industrial engine removal, repetitive lifting, or assembly line processes. In contrast, hydraulic engine hoists remain popular in automotive garages and repair shops due to their affordability, simplicity, and portability.

Engine Hoist Levelers: Essential for Safe, Precise Engine Removal

The primary purpose of an engine hoist is to lift, maneuver, and position heavy, awkward, or bulky materials safely and efficiently. For tasks where precise alignment is crucial—such as extracting an engine from a tight engine bay—an engine hoist leveler becomes invaluable. Levelers, also called load levelers or engine balancing bars, attach between the hoist and the engine to help maintain balance and adjust the engine's tilt during lifting.

Front-wheel drive and older model vehicles often provide clear access to the engine, making it easy to roll up the engine hoist and remove the engine. However, larger, modern engines frequently require tilting the engine to avoid obstacles like the firewall, transmission, or surrounding components. Load levelers offer multiple connection points—each adjustable by a crank handle or tightening bolt—allowing users to achieve the perfect tilt without shifting the lifting chains. This ensures the engine remains level from side to side, preventing twisting or dangerous movement during removal.

Load levelers come in various capacities, typically ranging from 500 pounds to two tons, and may feature two or four hooks depending on their design and intended load. Choosing the right leveler for your engine hoist setup enhances both safety and efficiency, especially when working on complex or high-performance engines.

Understanding the Boom: The Backbone of Engine Hoist Performance

The boom is the pivotal arm of an engine hoist, responsible for both lifting and stabilizing the load. It can be attached to a wall, frame, or mobile base. At the end of the boom, a chain and hook or load leveler is connected for secure lifting. Many engine hoists feature an adjustable boom, allowing users to extend or retract its reach, thereby increasing flexibility for different engine sizes and vehicle types.

In hydraulic engine hoists, the boom is raised and lowered by a hydraulic cylinder, while in electric hoists, an electric motor does the lifting. The strength and build of the boom directly determine the hoist’s maximum load capacity. Bear in mind: as the boom is extended outward, the lifting capacity decreases. It’s crucial to consult the manufacturer’s guidelines on safe load limits for each boom position to ensure safe operation and avoid equipment failure.

Types of Engine Hoists: Which is Right for You?

The three most common types of engine hoists are hydraulic, electric, and chain hoists. Each offers distinct advantages depending on the intended application and user requirements. Hoists may be configured as mobile units with four wheels, wall-mounted arms, or gantry systems for overhead lifting. Among these, electric hoists typically offer the highest lifting capacities, often supporting several tons for industrial use cases.

- Hydraulic Engine Hoists: Ideal for automotive repair and general workshop use, offering portability, affordability, and robust lifting power.

- Electric Engine Hoists: Best suited for industrial environments or repetitive lifting tasks, where speed and convenience are paramount.

- Chain Engine Hoists: Favored for their simplicity, low cost, and minimal maintenance in both DIY and professional settings.

Hydraulic Engine Hoist: Versatile and User-Friendly

Hydraulic engine hoists, sometimes referred to as shop cranes or cherry pickers, are the go-to choice for automotive mechanics, home garages, and small workshops. Featuring a hydraulic cylinder filled with oil, these hoists use manual pumping action to raise or lower the boom. Their sturdy steel frames, equipped with caster wheels, provide both durability and mobility for maneuvering engines around tight spaces.

Why choose a hydraulic engine hoist? They are generally more affordable than electric hoists, offer comparable lifting capacities (often up to 2 tons or more), and require minimal maintenance. The straightforward construction of hydraulic hoists makes them easy to operate, repair, and store. Popular applications include car engine removal, motorcycle engine swaps, and light industrial machinery handling.

- Typical lifting capacity: 1 to 3 tons

- Common features: Folding legs for compact storage, adjustable boom, integrated safety valves

- Best for: Automotive repair shops, DIY mechanics, small-scale engine work

Electric Engine Hoists: Power and Precision for Heavy Lifting

Electric engine hoists use a powerful electric motor to drive a drum and chain system, efficiently lifting and lowering heavy loads at the touch of a button. They are typically mounted to a gantry crane, fixed boom, or structural support beam, making them ideal for permanent installations in industrial facilities, assembly lines, or busy automotive shops.

What are the benefits of using an electric engine hoist? These hoists provide consistent lifting speed, remote operation (wired or wireless), and the capacity to handle frequent, repetitive tasks. As the rated capacity increases, so does the cost—making electric hoists best suited for users who need high efficiency and minimal manual effort. Many models feature advanced safety features, such as overload protection, emergency stop switches, and automatic brakes.

- Lifting capacities: 1/2 ton to 5+ tons (higher for industrial models)

- Features: Wireless remotes, variable speed control, integrated safety sensors

- Best for: Factories, warehouses, large-scale engine assembly, marine engine installation

Chain Engine Hoists: Simple, Reliable, and Affordable

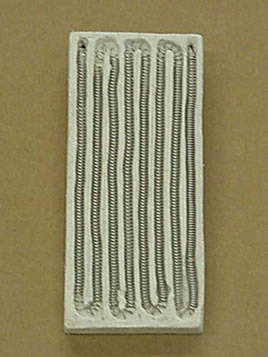

Chain engine hoists, also known as manual chain blocks or hand chain hoists, utilize a system of gears and chains to provide mechanical lifting force. To operate, the user pulls a hand chain, activating a gear train that multiplies force and lifts the load via a load chain and hook. These hoists include a ratchet or braking system for safety, preventing accidental lowering when the drive chain is released.

Chain engine hoists are typically mounted on a gantry, beam clamp, or boom, offering a low-cost, low-maintenance solution for occasional lifting tasks. While they operate more slowly than powered hoists and require manual effort, their simplicity makes them a favorite among small workshops, DIYers, and budget-conscious buyers. For more details on different chain hoist models and suppliers, visit our Chain Hoist Manufacturers directory.

- Load capacity: 1/2 ton to 5 tons (depending on model)

- Advantages: Low cost, minimal maintenance, reliable operation

- Best for: Occasional use, small workshops, backup lifting device

Key Applications and Use Cases for Engine Hoists

Engine hoists are indispensable across a range of industries and settings. Here are some of the most popular use cases:

- Automotive Repair and Restoration: Removing or installing car and truck engines, performing engine swaps, and handling transmissions or differentials.

- Industrial Maintenance: Lifting pumps, compressors, or other heavy equipment for repair or replacement.

- Marine Applications: Hoisting boat engines, marine generators, and related components for maintenance or installation.

- Manufacturing and Assembly: Moving heavy parts or machinery on production lines, particularly in engine assembly plants.

- Warehouse and Material Handling: Loading/unloading engines and machinery from trucks, organizing inventory, and supporting logistics operations.

Benefits of Using an Engine Hoist

Why invest in an engine hoist? Here are some compelling advantages:

- Improved Safety: Engine hoists reduce the risk of injuries associated with manual lifting, heavy strain, or awkward body positions.

- Increased Efficiency: Tasks that once required multiple people can be performed by a single operator, speeding up repairs and installations.

- Versatility: Engine hoists can be used for a wide range of lifting and positioning tasks beyond automotive engines, such as moving generators, transmissions, or industrial machinery.

- Portability: Many engine hoist models are foldable or feature caster wheels, enabling easy transport and storage.

- Cost-Effective: Investing in a quality engine hoist can save on labor costs and reduce downtime during repairs or installations.

How to Choose the Right Engine Hoist: Key Factors and Decision Criteria

Searching for the best engine hoist for your needs? Consider the following factors to make an informed decision:

- Load Capacity: Ensure the hoist can safely handle the maximum weight you plan to lift. Always allow for a margin of safety above your typical load.

- Lift Height and Reach: Consider the vertical and horizontal reach required to access and remove/install your engine or load.

- Hoist Type: Decide between hydraulic, electric, or manual chain models based on your workload, frequency of use, and available power sources.

- Portability and Storage: Foldable or wheeled hoists are easier to move and store when not in use.

- Build Quality and Safety Features: Look for sturdy steel construction, reinforced welds, safety valves, overload protection, and reliable brakes.

- Budget: Factor in not only the purchase price but also long-term maintenance, part availability, and warranty support.

- Supplier Reputation: Choose a reputable engine hoist manufacturer or distributor with strong customer reviews, technical support, and clear warranty policies.

Still unsure? Ask yourself:

- What is the heaviest engine or component I’ll need to lift?

- Will I need to move the hoist between locations, or is it for permanent installation?

- Do I have access to power outlets for electric hoists, or is manual/hydraulic operation preferable?

- Will I be lifting engines frequently, or only occasionally?

Frequently Asked Questions about Engine Hoists

What safety precautions should I follow when using an engine hoist?

Always inspect the hoist, chains, and hooks for wear or damage before use. Never exceed the rated capacity. Use proper lifting points on the engine and avoid sudden movements. Keep bystanders clear of the load, and ensure the hoist is on a flat, stable surface. Refer to the manufacturer’s manual for detailed safety guidelines.

Can I use an engine hoist for other lifting tasks?

Yes. While engine hoists are designed primarily for engines, they can be used to lift transmissions, differentials, generators, and even small machinery—provided you do not exceed the weight capacity and use appropriate lifting attachments.

How do I maintain my engine hoist?

Regularly inspect and lubricate moving parts, check hydraulic fluid levels in hydraulic hoists, and tighten bolts or fasteners. Store the hoist in a dry environment to prevent rust. Follow all manufacturer maintenance instructions to ensure safe operation and extend the life of your equipment.

What brands are considered reliable for engine hoists?

Top-rated engine hoist manufacturers include names like Torin, Strongway, Sunex, OTC, and Harbor Freight. Always research customer reviews and supplier support before purchasing.

Choosing the Right Engine Hoist Supplier

For the most beneficial outcome when purchasing an engine hoist from an engine hoist supplier, it is important to compare several companies using our directory of engine hoist suppliers. Each engine hoist company has a business page profile illustrating their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each engine hoist business website using our proprietary website previewer for an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple engine hoist businesses with the same form.

Ready to find the best engine hoist for your workshop or industrial needs? Compare engine hoist suppliers now, or request a quote to get personalized recommendations and pricing tailored to your application.

Ready to upgrade your lifting equipment? Explore our comprehensive guides, compare top-rated engine hoist brands, and request a quote to streamline your purchasing process today.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches