More Electric Hoist Manufacturers

Electric hoists are indispensable across countless industries and operational environments. As automated lifting devices powered by electric motors, they are critical for safely and efficiently transporting materials, equipment, and products. You’ll find electric hoists in manufacturing plants, construction sites, warehouses, ports, shipyards, and even residential settings—anywhere heavy loads require reliable, precise movement. Their capacity to lift and position substantial weights with accuracy, coupled with their user-friendly operation, makes them essential for assembling large machinery, handling cargo, setting up structural elements, and facilitating maintenance and repair tasks. This adaptability, combined with robust lifting capabilities and advanced safety features, establishes electric hoists as a vital material handling solution across diverse sectors.

Components of Electric Hoists

An electric hoist consists of several integral components, each fulfilling a unique function to ensure safe and efficient operation. Understanding the anatomy of an electric hoist helps buyers evaluate which features best suit their lifting requirements:

- Electric Motor: The powerhouse of the hoist, converting electrical energy into mechanical motion to drive the lifting mechanism. Motor specifications—including voltage, phase (single or three-phase), and power rating—directly impact performance and load capacity.

- Brake System: A critical safety feature, the brake system automatically activates to prevent the load from descending unintentionally when the motor stops. This ensures load stability, reduces risks of accidents, and is especially important for overhead lifting.

- Gearbox: The gearbox translates the high-speed rotation of the motor into the high-torque, low-speed output necessary for heavy lifting. Gear design and quality affect efficiency, durability, and smooth operation.

- Lifting Medium (Wire Rope or Load Chain): The primary link between the hoist and the load, engineered for strength and reliability. Wire rope is favored for heavy-duty, high-lift applications, while load chains are common in more compact or moderate-capacity hoists.

- Hook or Lifting Attachment: The interface between the hoist and the payload, typically featuring safety latches or swivels to prevent accidental disengagement. Selecting a properly rated hook is fundamental to safe operation.

- Control System: The “brain” of the hoist, providing operators with precise control over lifting speed, direction, and positioning. Controls range from simple push-button pendants to advanced remote or wireless systems, and may include variable speed drives for delicate tasks.

- Safety Features: Modern electric hoists incorporate limit switches (to prevent over-travel), overload protection (to avoid exceeding rated capacity), and emergency stop buttons for rapid response in critical situations. Some hoists integrate load sensors or load cells, providing real-time weight data to assist operators in preventing overloading and optimizing safety.

- Remote Control Systems: Allow operators to manage hoist functions from a safe distance, reducing exposure to hazardous environments and increasing operational flexibility.

By integrating these key components, electric hoists achieve the efficiency, safety, and reliability demanded by today’s industrial and commercial material handling applications.

Types of Electric Hoists

Electric hoists come in a variety of types, each engineered to address specific lifting challenges and application requirements. When researching electric hoists, understanding the differences between wire rope hoists, chain hoists, mini hoists, and explosion-proof hoists will help you make the best selection for your needs.

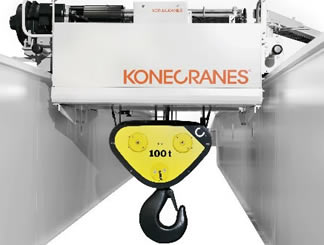

Wire Rope Hoists

Wire rope hoists utilize a steel wire rope wound around a grooved drum to lift and lower loads. These hoists are the go-to solution for heavy-duty, high-capacity lifting tasks in industrial, construction, and infrastructure projects. Key features include:

- High Load Capacities: Wire rope hoists can handle loads from several hundred kilograms up to 100 tons or more, making them ideal for applications such as bridge building, heavy equipment manufacturing, and shipyards.

- Superior Lifting Heights: The design allows for longer lifting distances compared to chain hoists, which is especially useful in tall warehouses or multi-story construction sites.

- Durability and Longevity: Wire ropes offer excellent resistance to abrasion and wear, maintaining performance in demanding or harsh environments.

- Precision Control: Many wire rope hoists offer advanced speed control for accurate positioning of heavy or delicate loads.

While offering unparalleled strength and longevity, wire rope hoists typically require more maintenance and have a higher initial investment than chain hoists. However, their capabilities and reliability often deliver a strong return on investment for industrial buyers.

Chain Hoists

Chain hoists employ a hardened alloy steel load chain as the lifting medium, delivering a compact and versatile solution for a wide range of lifting tasks. Commonly used in workshops, automotive garages, and warehouse settings, chain hoists feature:

- Portability and Compact Size: Their smaller footprint and lighter weight make chain hoists easy to install, relocate, and use in tight or overhead spaces.

- Cost-Effectiveness: Generally more affordable than wire rope hoists, chain hoists are a popular option for businesses with moderate lifting requirements or budget constraints.

- Reliability: The simple, rugged mechanism ensures consistent performance with minimal maintenance.

- Range of Capacities: Chain hoists are available in models capable of lifting loads from a few hundred pounds up to several tons.

It’s important to note that chain hoists usually offer lower lifting heights and can experience chain wear or fatigue over time, necessitating periodic inspection and replacement for optimal safety.

Mini Electric Hoists

Mini electric hoists are compact, lightweight, and designed for lighter loads, making them ideal for residential, small business, or light industrial use. Popular applications include:

- Lifting household appliances, HVAC units, or small machinery

- Supporting home renovations or garage operations

- Portable lifting solutions for contractors or service professionals

Mini hoists are valued for their ease of installation, portability, and affordable price point. However, their maximum lifting capacity is limited (typically up to 500kg), so they are not intended for heavy industrial or continuous-duty operations.

Explosion-Proof Electric Hoists

Explosion-proof electric hoists are engineered for use in hazardous locations where flammable gases, vapors, or dust may be present. These hoists are constructed to prevent sparks or excessive heat, reducing the risk of ignition in volatile atmospheres. Key use cases include:

- Oil & gas refineries

- Chemical and pharmaceutical plants

- Mining operations

- Paint shops and grain handling facilities

Explosion-proof hoists comply with strict safety standards (such as ATEX, IECEx, or NEC) and incorporate special enclosures, sealed components, and non-sparking materials. While offering essential protection, their specialized design often results in higher costs and may slightly limit maximum load capacities.

Considerations Regarding Electric Hoists

While electric hoists offer a host of advantages, several critical factors should be weighed during the selection process:

- Initial Cost: Electric hoists typically require a higher upfront investment compared to manual or pneumatic hoists, but the gains in productivity, safety, and efficiency often justify the expense for frequent or heavy lifting operations.

- Power Source Availability: Access to reliable electricity is necessary for operation. In remote or outdoor locations without power, consider whether battery-powered, manual, or air-powered hoists may be more suitable alternatives.

- Suitability for Hazardous Environments: Standard electric hoists are not appropriate for locations with high explosion or fire risks unless specifically certified as explosion-proof.

- Maintenance Requirements: Routine inspection, lubrication, and replacement of wear components (such as wire ropes or chains) are essential for safe, long-term use.

- Space and Installation Constraints: Carefully evaluate mounting requirements, headroom, and available space to ensure compatibility with the intended environment.

Thinking through these factors will help you choose a hoist system that aligns with your operational needs, regulatory requirements, and budget.

Benefits of Electric Hoists

Electric hoists stand out as premier lifting solutions in manufacturing, construction, logistics, and beyond. Key benefits include:

- Superior Lifting Capacity: Electric hoists handle loads that would be unmanageable or unsafe with manual lifting, promoting a safer and more productive work environment.

- Enhanced Workplace Safety: By reducing the physical demands on workers, electric hoists lower the risk of musculoskeletal injuries, accidents, and fatigue-related errors.

- Precision and Control: Electric motors deliver steady, adjustable lifting speeds, allowing for gentle handling of delicate goods or pinpoint placement of heavy assemblies.

- Versatility: With a wide range of sizes, mounting options (top-running, underhung, portable), and feature sets, electric hoists can be tailored to virtually any lifting challenge—indoors or out, light or heavy duty.

- Ease of Use: Intuitive controls make electric hoists accessible even to operators with limited training, streamlining workflows and increasing overall efficiency.

- Integration with Automation: Many modern electric hoists can be incorporated into automated systems or overhead cranes, further optimizing material flow and throughput.

- Advanced Safety Features: Overload protection, automatic braking, and emergency stops protect personnel and equipment, while optional load monitoring systems help prevent accidents before they occur.

- Eco-Friendliness: Powered by electricity rather than fossil fuels, electric hoists produce no direct emissions and support sustainability initiatives.

When evaluating the advantages of electric hoists, consider how these benefits translate into higher productivity, lower operating costs, and improved regulatory compliance for your specific application.

Applications of Electric Hoists

Owing to their versatility and robust design, electric hoists find essential use in a wide spectrum of industries and applications. Common examples include:

- Manufacturing and Assembly: Electric hoists streamline the movement of raw materials, work-in-progress items, and finished goods throughout production lines. They’re especially vital for lifting machinery, dies, molds, and assembly components in automotive, aerospace, and heavy equipment plants.

- Construction: Hoists efficiently transport steel beams, precast panels, concrete blocks, scaffolding, and construction tools to different levels of a building site. Their reliability supports both structural assembly and material staging for efficient project workflows.

- Warehousing and Logistics: In distribution centers and storage facilities, electric hoists lift and position pallets, crates, and containers, aid in loading/unloading trucks, and facilitate high-density racking systems to maximize space utilization.

- Automotive: Automotive workshops rely on electric hoists for lifting vehicles, engines, transmissions, and other heavy components, enabling safe and precise service or repair work.

- Mining and Drilling: Electric hoists are used to lift heavy mining equipment, drilling rigs, piping, and extracted materials. Their robust construction ensures reliable performance in both underground and surface operations, even under extreme environmental conditions.

- Marine and Shipbuilding: In shipyards, ports, and marinas, electric hoists handle cargo, containers, and ship components, as well as assist in the lifting and maintenance of vessels.

- Utilities and Energy: Hoists are indispensable for handling transformers, turbines, and other heavy equipment in power plants and substations.

- Entertainment and Event Production: Specialized electric hoists are used to raise lighting rigs, scenery, and sound equipment in theaters, arenas, and studios, offering precision and safety for intricate setups.

- Residential and Small Business: Mini electric hoists facilitate the lifting of appliances, furniture, or garage projects, making them valuable for homeowners, contractors, and service technicians.

Want to find the best electric hoist for your specific industry or application? Explore our directory of manufacturers and compare models tailored to your lifting needs.

Selecting the Correct Electric Hoist

Choosing the right electric hoist involves more than just matching lifting capacity. Consider these key decision factors to ensure optimal performance, safety, and value:

- Load Capacity: Determine the maximum weight to be lifted, including any potential future increases. Always select a hoist with a rated capacity at or above your heaviest anticipated load.

- Lifting Height: Measure the vertical distance the load must travel. Choose a hoist with sufficient drum or chain length to accommodate your application.

- Duty Cycle and Frequency of Use: Assess how often and for how long the hoist will operate daily. Heavy-duty, continuous-use environments require robust, industrial-grade hoists with higher duty ratings to prevent overheating and premature wear.

- Mounting Options: Consider whether you need a fixed or portable hoist, top-running or underhung configuration, and the type of support structure (beam, trolley, gantry, or jib crane).

- Space Constraints: Evaluate available headroom, floor space, and access for installation and maintenance.

- Power Requirements: Match the hoist to your facility’s voltage and phase. Some environments may benefit from hoists with dual-voltage or variable-frequency drive capabilities.

- Control Preferences: Decide between pendant, remote, or wireless controls. For hazardous areas, confirm compatibility with explosion-proof or intrinsically safe control options.

- Safety Features: Prioritize models with overload protection, limit switches, emergency stop functions, and, where applicable, load monitoring or anti-drop mechanisms.

- Compliance and Certification: Ensure the hoist meets all relevant industry standards and safety regulations (OSHA, ANSI, ASME, CE, ATEX, etc.).

- Supplier Reputation: Work with established manufacturers known for quality, warranty support, and availability of spare parts and service.

- Budget and Total Cost of Ownership: Factor in not only initial purchase price, but also maintenance, warranty coverage, and expected lifespan.

Still unsure which hoist fits your application? Ask our experts or use our supplier comparison tools to get personalized recommendations based on your project requirements.

Choosing the Correct Electric Hoist Company

For the best results when purchasing an electric hoist, a thorough supplier comparison is crucial. Here’s how to make your buying process more efficient and effective:

- Leverage Our Supplier Directory: Access a curated list of top electric hoist manufacturers and distributors, each with detailed profiles outlining their capabilities, certifications, and areas of expertise.

- Use the Contact and RFQ Forms: Reach out directly to suppliers for quotes or technical questions, or use our Request for Quote (RFQ) tool to contact multiple companies at once—saving you time and streamlining the procurement process.

- Utilize the Patented Website Previewer: Quickly assess each supplier’s specialties and product range to narrow down your shortlist.

- Evaluate Support Services: Consider after-sales support, warranty terms, technical assistance, and the availability of replacement parts as part of your decision-making process.

- Compare Lead Times and Customization Options: Some projects may require fast delivery or tailored solutions, so be sure to inquire about these aspects during your supplier search.

Ready to take the next step? Start your search for the best electric hoist supplier here, or request quotes from multiple companies to compare quality, price, and support.

Frequently Asked Questions About Electric Hoists

- What are the main differences between electric, manual, and pneumatic hoists?

Electric hoists offer faster lifting speeds, greater load capacities, and advanced safety features compared to manual hoists, which rely on human effort. Pneumatic (air-powered) hoists are favored in explosion-prone environments but require a compressed air source. - How do I maintain an electric hoist for long-term reliability?

Regularly inspect all components, lubricate moving parts, check wire ropes or chains for wear, and test safety features. Follow the manufacturer’s maintenance schedule and keep detailed records for compliance and warranty purposes. - Can electric hoists be used outdoors?

Yes, but choose weatherproof or specifically rated outdoor models. Ensure protection against rain, dust, and temperature extremes for optimal performance and safety. - What is the typical lifespan of an electric hoist?

With proper maintenance, industrial-grade electric hoists can last 10-20 years or more, though this depends on usage intensity, environment, and adherence to service intervals. - Are there electric hoists suitable for cleanroom or food-grade environments?

Yes. Choose stainless steel or coated hoists designed for sterile or hygienic applications, and ensure compliance with relevant standards (such as FDA or GMP). - Where can I get replacement parts or service for my electric hoist?

Most reputable manufacturers and distributors offer spare parts, technical support, and maintenance services. Use our directory to locate authorized service providers near you.

Next Steps: Find the Right Electric Hoist for Your Needs

Whether you’re sourcing an industrial-grade wire rope hoist, a compact chain hoist for tight spaces, or a specialized explosion-proof model, getting the right equipment is critical for safe and productive operations. Start by defining your application’s requirements, then compare suppliers and solutions using our industry-leading directory and RFQ tools. Need help or want expert advice? Contact our team for personalized hoist recommendations.

For additional details, technical guides, or to browse top-rated electric hoist manufacturers, visit our comprehensive resource center or explore related categories such as chain hoists and portable hoists.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches