Chain hoists are powerful and reliable tools widely used in various industries for lifting and moving heavy loads. These electrically powered devices offer a multitude of applications, making them indispensable in manufacturing, construction, warehousing, entertainment, automotive, and transportation sectors, among others. Chain hoists provide a safe and efficient solution for lifting operations, allowing for precise control and ease of operation. Read More…

At Spanco, Inc., we take pride in designing and manufacturing high-performance lifting solutions that improve efficiency, safety, and productivity across industrial environments. As a leading producer of electric hoists and overhead crane systems, we bring together decades of engineering expertise and precision craftsmanship to create equipment that supports a wide range of material handling...

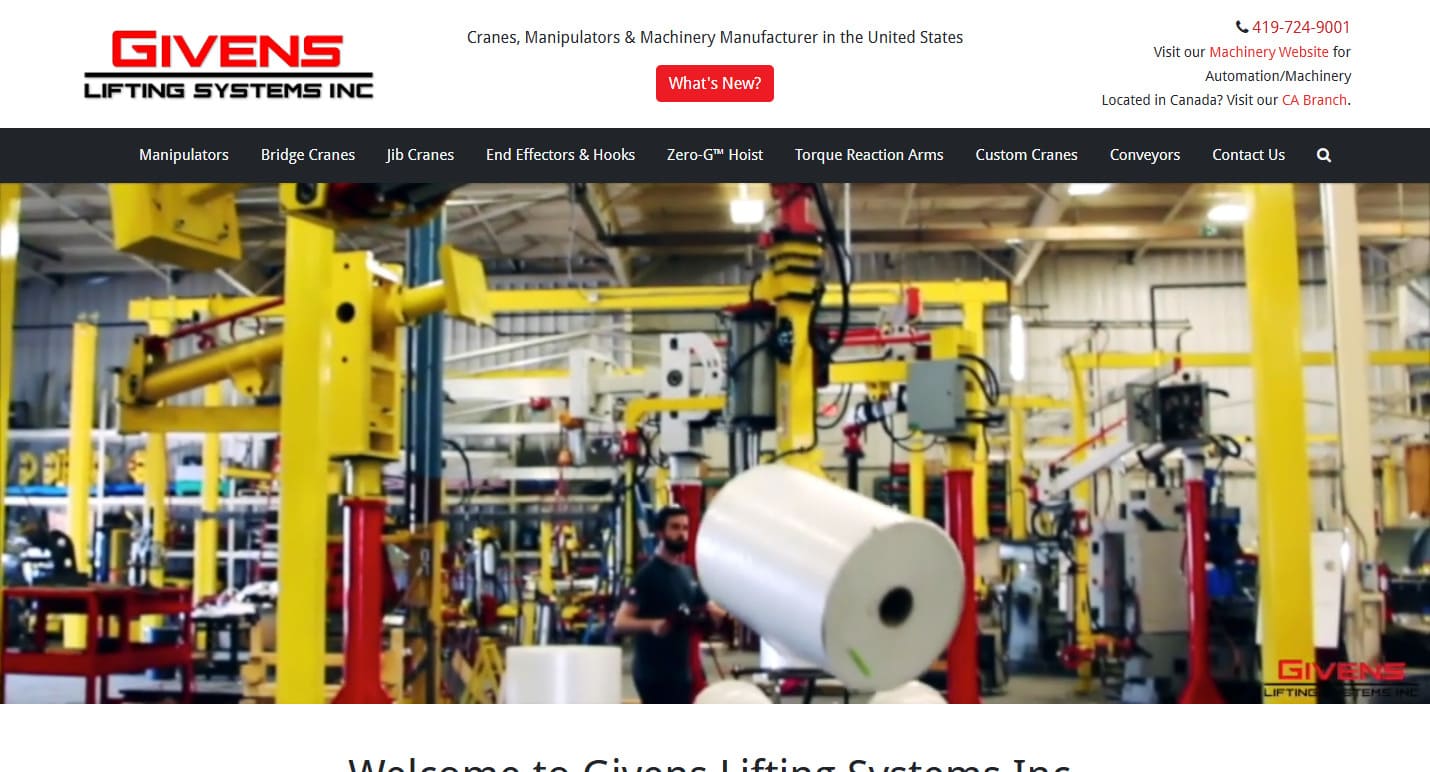

We are Givens Lifting Systems, Inc., a leading company specializing in providing high-quality lifting solutions, with a primary focus on cranes. With our extensive expertise and commitment to innovation, we have established ourselves as a trusted partner for various industries worldwide.

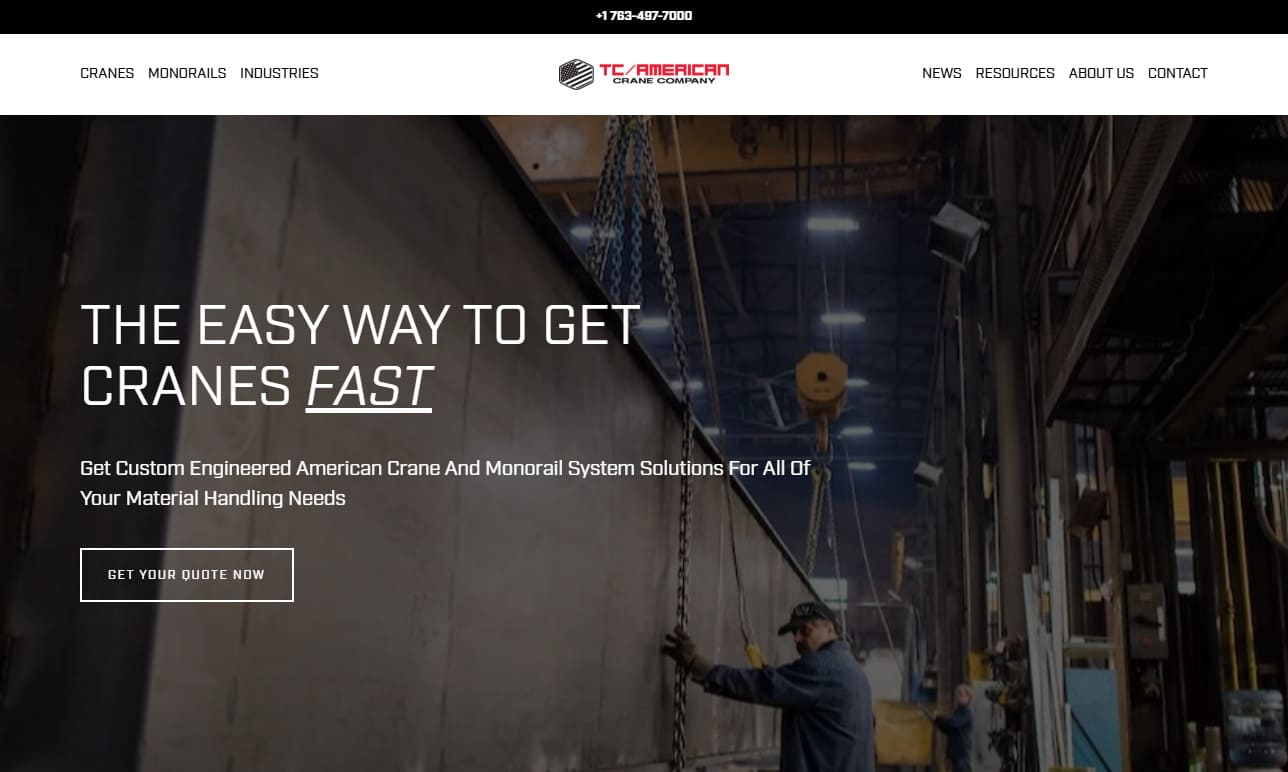

At TC/American Crane Company, we position ourselves as a trusted partner for customers who rely on safe, efficient, and durable lifting solutions. We design and manufacture electric hoists and integrated crane systems that help streamline material handling in demanding environments.

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

More Chain Hoist Manufacturers

Components of Chain Hoists

Chain hoists, also commonly referred to as chain block hoists or electric chain hoists, are engineered with several essential components that work seamlessly together to facilitate smooth, secure, and efficient lifting operations in industrial, commercial, and even some residential environments. Understanding the anatomy of a chain hoist is crucial for those evaluating different hoist types for material handling solutions or seeking to optimize their lifting equipment for specific applications.

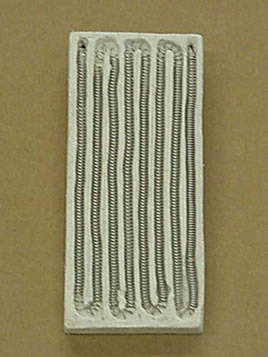

- Load Chain: The load chain is the core mechanical element responsible for bearing the weight of the load. Manufactured from high-strength, heat-treated alloy steel, this chain offers exceptional durability, resistance to abrasion, and the ability to handle heavy-duty lifting cycles. Some premium models utilize nickel-plated or corrosion-resistant chains for use in harsh or outdoor environments.

- Electric Motor: In electric chain hoists, a robust and energy-efficient electric motor provides the necessary power to lift and lower loads. These motors are designed for consistent performance and can be tailored for single-phase or three-phase power supplies, depending on the industrial application.

- Manual or Lever Mechanism: In manual chain hoists (commonly termed hand chain blocks), a hand-operated lever or chain wheel is used to operate the hoist, making them ideal for settings without access to electrical power or where mobility is required.

- Control System: The control pendant or remote control enables operators to precisely regulate the lifting and lowering process. Advanced models may include variable speed controls, programmable limit switches, and emergency stop features, ensuring both efficiency and safety in overhead lifting tasks.

- Chain Drive Mechanism: This assembly transfers power from the motor (or manual input) to the load chain, facilitating smooth, controlled movement. The gearing and braking system are engineered for minimal energy loss and maximum reliability.

- Hooks and Suspension: Both the top hook (for attachment to a beam, trolley, or fixed point) and the bottom hook (for connecting to the load) are forged from heavy-duty steel and feature safety latches to prevent accidental disengagement during operation.

- Safety Features: Modern chain hoists are equipped with overload protection devices, slip clutches, upper and lower limit switches, and emergency stop mechanisms, all designed to enhance operator safety and minimize risk of equipment damage.

These components work together to ensure chain hoists deliver reliable lifting, load control, and safety—even in demanding environments. If you’re wondering, “What features should I look for when choosing a chain hoist?” consider how each of these core elements impacts performance, longevity, and ease of maintenance.

Variations of Chain Hoists

Chain hoists are available in multiple configurations to accommodate a wide spectrum of lifting requirements and industrial applications. Choosing the right type of chain hoist can significantly impact productivity, workplace safety, and operating costs. Below are the most common variations you’ll encounter when researching and comparing chain hoisting equipment:

- Manual Chain Hoists (Hand Chain Blocks): Operated by pulling a hand chain, these models are simple, portable, and require no external power supply. They are often used in maintenance tasks, fieldwork, and locations where electrical outlets are not readily available.

- Lever Hoists: Also known as ratchet lever hoists, these are manually operated with a lever handle and are perfect for tensioning, pulling, and lifting applications in tight spaces.

- Electric Chain Hoists: Powered by an electric motor, these hoists deliver higher lifting speeds, consistent performance, and reduced operator fatigue. They are ideal for repetitive or high-capacity lifting tasks in manufacturing, assembly lines, and warehouses.

- Pneumatic (Air) Chain Hoists: Utilized in environments where electric motors are unsuitable, such as explosive atmospheres or locations with strict fire safety requirements. Pneumatic hoists offer smooth, variable speed control and are resistant to heat and dust.

- Single-Speed Chain Hoists: Offer a fixed lifting speed, making them dependable for applications where predictable, uniform movement is necessary.

- Variable-Speed Chain Hoists: Feature adjustable lifting speeds, allowing operators to tailor the speed to the load, the environment, or the specific handling requirements. This versatility helps prevent load swing and increases placement accuracy.

- Low-Headroom Chain Hoists: Engineered for spaces with minimal overhead clearance, these compact models allow maximum lifting height in restricted environments, such as underground facilities, compact workshops, or mezzanines.

- Explosion-Proof Chain Hoists: Built to stringent safety standards, these hoists are equipped with specially designed motors, enclosures, and anti-sparking components, making them suitable for hazardous areas such as petrochemical plants, grain silos, and chemical processing facilities.

Are you searching for the right chain hoist for a specific application? Consider factors such as available power sources, load weight, duty cycle, frequency of use, and environmental hazards before making a decision. Learn more about chain hoist types and their unique advantages to select the best fit for your industry or project.

Considerations Regarding Chain Hoists

While chain hoists offer a host of advantages and are integral to many material handling operations, buyers and facility managers must weigh several key considerations before purchase or installation. Addressing these factors early on can help prevent operational disruptions and maximize your return on investment:

- Initial Investment and Installation: Electric and pneumatic chain hoists, particularly those with advanced features, may require a higher upfront investment and specialized installation. This includes the cost of structural supports, beam trolleys, and electrical or pneumatic supply lines.

- Maintenance and Downtime: Regular inspection, lubrication, and component replacement (such as load chains and hooks) are vital to maintain safe operation and extend equipment lifespan. Some advanced models offer self-diagnostics or IoT-based maintenance alerts to minimize unscheduled downtime.

- Mobility and Flexibility: Fixed-mount chain hoists provide stability but limited portability. If your operation requires frequent relocation or lifting in multiple areas, consider portable manual hoists or systems designed for easy movement along a crane beam or monorail.

- Environmental Suitability: Not all chain hoists are rated for outdoor use or exposure to corrosive elements, moisture, or dust. Choose models with appropriate ingress protection (IP) ratings, weatherproof coatings, or stainless steel chains for challenging environments.

- Operator Training and Ergonomics: Proper training is essential to ensure safe use and prevent workplace injuries. Opt for hoists with user-friendly controls, ergonomic handles, and clear safety labeling.

Benefits of Chain Hoists

Despite the aforementioned considerations, the benefits of chain hoists make them an indispensable component of modern lifting and material handling systems. Whether you’re upgrading warehouse equipment, designing a new production line, or managing a construction site, chain hoists deliver tangible advantages that support safety, efficiency, and productivity:

- High Lifting Capacities: Chain hoists are engineered to handle loads ranging from a few hundred kilograms to several tons, making them suitable for everything from light-duty workshop tasks to heavy industrial lifting operations.

- Precision Load Control: Advanced control systems, including variable speed drives and load sensors, enable operators to lift, lower, and position heavy or delicate loads with remarkable accuracy. This is especially valuable in applications such as assembly, maintenance, and machine installation.

- Enhanced Safety: Safety features like overload protection, emergency stops, limit switches, and automatic brakes help prevent accidents, protect operators, and reduce workplace liability. Many models are compliant with international safety standards such as ASME, OSHA, and CE.

- Durability and Longevity: Built for industrial use, chain hoists feature rugged construction and corrosion-resistant finishes that stand up to harsh environments and intensive duty cycles. With regular maintenance, a quality chain hoist can provide decades of reliable service.

- Versatility: Chain hoists can be used in stationary, mobile, or integrated crane systems. Their modular design allows for easy upgrades, accessory integration, and adaptation to changing material handling needs.

- Cost-Effective Solution: Compared to alternative lifting solutions like wire rope hoists or hydraulic lifts, chain hoists often offer lower initial costs, reduced maintenance expenses, and a better long-term value proposition for many applications.

If you’re evaluating the advantages of chain hoists vs. other lifting equipment, consider operational requirements, safety standards, and total cost.

Applications of Chain Hoists

Chain hoists are renowned for their adaptability and reliability across a diverse range of industries and use cases. Their robust lifting capacity and precise control make them a preferred choice for applications where safety, efficiency, and repeatability are paramount. Explore the many ways chain hoists support critical operations:

- Manufacturing and Industrial Production: Used for lifting heavy machinery, molds, dies, and assembly components. Chain hoists streamline production lines, reduce manual handling, and facilitate equipment maintenance.

- Construction and Building Projects: Essential for hoisting structural steel, concrete forms, prefabricated panels, and large construction materials to various heights safely and efficiently. Chain hoists help minimize labor and accelerate project timelines.

- Warehousing and Material Handling: Optimize space utilization by enabling vertical lifting of pallets, crates, and inventory in environments with limited floor space or height restrictions. Chain hoists are often integrated with overhead cranes or gantry systems.

- Entertainment and Stage Rigging: Stage and event professionals use chain hoists to precisely position lighting grids, sound equipment, and set pieces. Motorized chain hoists allow for dynamic scene changes and ensure performer safety.

- Automotive and Transportation: Indispensable for lifting engines, suspensions, transmissions, and other heavy vehicle components during repairs, maintenance, and assembly.

- Mining, Oil, and Gas: Explosion-proof and corrosion-resistant chain hoists are vital for moving equipment and materials in underground mines, refineries, and offshore drilling rigs where hazardous conditions exist.

- Marine and Shipbuilding: Used for installing ship engines, winches, and heavy components in dockyards and shipyards, where precise load handling is required in challenging environments.

- Utilities and Infrastructure: Facilitate maintenance and installation of transformers, turbines, and heavy electrical equipment in power plants, water treatment facilities, and utility stations.

Curious about how chain hoists can optimize your workflow? Discover detailed case studies and industry-specific applications of chain hoists to see their advantages in action. For personalized recommendations, contact our chain hoist experts today.

The Future of Chain Hoists

The future of chain hoist technology is being shaped by rapid advancements in automation, digitalization, and materials science. As industries pursue greater efficiency, safety, and environmental responsibility, manufacturers are developing innovative features that redefine what chain hoists can achieve. Here’s what to expect in the coming years:

- Automation and Smart Control: Integration with programmable logic controllers (PLCs), intelligent sensors, and remote diagnostics enables autonomous lifting operations, predictive maintenance, and real-time load monitoring. This reduces operator intervention and helps prevent system failures.

- Internet of Things (IoT) Connectivity: Next-generation chain hoists will feature IoT-enabled devices for remote monitoring, firmware updates, and automated maintenance alerts. Facility managers can track equipment health, usage statistics, and compliance from any location.

- Lightweight and Compact Designs: Advances in alloy materials, engineering plastics, and modular construction allow for smaller, lighter hoists with the same or greater lifting capacity. This enhances portability and installation flexibility, especially in retrofitted or mobile applications.

- Increased Safety and Ergonomics: New safety innovations—such as advanced overload protection, enhanced braking systems, and fail-safe limit switches—continue to reduce the risk of accidents. Ergonomically designed controls and wireless remotes improve operator comfort and productivity.

- Eco-Friendly and Energy-Efficient Operation: Energy-saving electric motors, regenerative braking, and low-power standby modes are being integrated to minimize operational costs and environmental impact. Some manufacturers are exploring the use of recycled materials and sustainable manufacturing processes for chain hoist production.

Are you interested in emerging trends in chain hoist technology? Read the latest updates on smart hoists, IoT integration, and sustainability in lifting solutions to stay ahead of the curve.

Choosing the Correct Chain Hoist Manufacturer

Finding a reputable, experienced chain hoist manufacturer is critical to ensuring safe, efficient, and reliable lifting operations. From product selection to after-sales support, the right manufacturer will offer expertise, customization, and value-added services that match your unique requirements. Here’s how to make an informed decision:

- Evaluate Experience and Capabilities: Review manufacturer profiles to assess their specialization in specific hoist types, load capacities, safety certifications, and industry focus. Some companies offer tailored hoist solutions for sectors like automotive, construction, or petrochemicals.

- Check Product Range and Customization: Look for companies that provide a broad selection of manual, electric, and pneumatic chain hoists, as well as specialized options like explosion-proof or ultra-low headroom models. Customization services, such as custom lifting heights, control systems, and mounting options, ensure the hoist meets your facility’s needs.

- Analyze Quality Assurance and Compliance: Ensure the manufacturer adheres to recognized quality and safety standards, such as ISO 9001, ASME, ANSI, or CE. Certifications reflect rigorous testing and compliance with international regulations.

- Consider After-Sales Support and Parts Availability: Reliable manufacturers offer comprehensive warranties, technical support, spare parts inventory, and training programs for operators and maintenance technicians.

- Request Quotes and Compare Value: Use our directory of chain hoist manufacturers to request quotes, compare features, and evaluate total cost of ownership—not just purchase price. Our patented website previewer and RFQ form streamline the comparison process.

Ready to find the best chain hoist manufacturer for your project? Browse our directory of chain hoist manufacturers or request a quote to connect with industry leaders and receive expert guidance on your lifting requirements.

Frequently Asked Questions About Chain Hoists

- What is the difference between a chain hoist and a wire rope hoist? Chain hoists use a load chain and are typically favored for shorter lift heights and moderate loads, while wire rope hoists use a steel wire rope and are better suited for longer lifts and higher capacities.

- How do I determine the right capacity for my chain hoist? Calculate the maximum load weight, include a safety margin, and consider any attachments or slings. Consult manufacturer specifications and use our load calculator for precise sizing.

- What maintenance is required for chain hoists? Regularly inspect load chains for wear, lubricate moving parts, check for proper function of brakes and limit switches, and follow the manufacturer's recommended service intervals.

- Can chain hoists be integrated with cranes or trolleys? Yes, most chain hoists are designed for compatibility with overhead cranes, monorail systems, and beam trolleys for enhanced flexibility and movement. Review our chain hoist integration guide for tips on seamless installation.

- What safety standards apply to chain hoists? Look for compliance with OSHA, ASME B30.16, ANSI, and CE standards, which govern hoist design, operation, and maintenance. Manufacturers should provide documentation and certification upon request.

Still have questions or need expert advice on selecting, installing, or maintaining chain hoists? Contact our team of lifting equipment specialists for personalized recommendations and technical support.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches