Engine lifts are designed to lift, remove, and transport engines for repair and examination. They use a hoist with wire rope or chain to lift an engine from its mountings. Engine lifts can be hydraulic, electric, or manually chain-driven. They are portable and can be easily attached to an engine using chains and a hook. Read More…

At Spanco, Inc., we take pride in designing and manufacturing high-performance lifting solutions that improve efficiency, safety, and productivity across industrial environments. As a leading producer of electric hoists and overhead crane systems, we bring together decades of engineering expertise and precision craftsmanship to create equipment that supports a wide range of material handling...

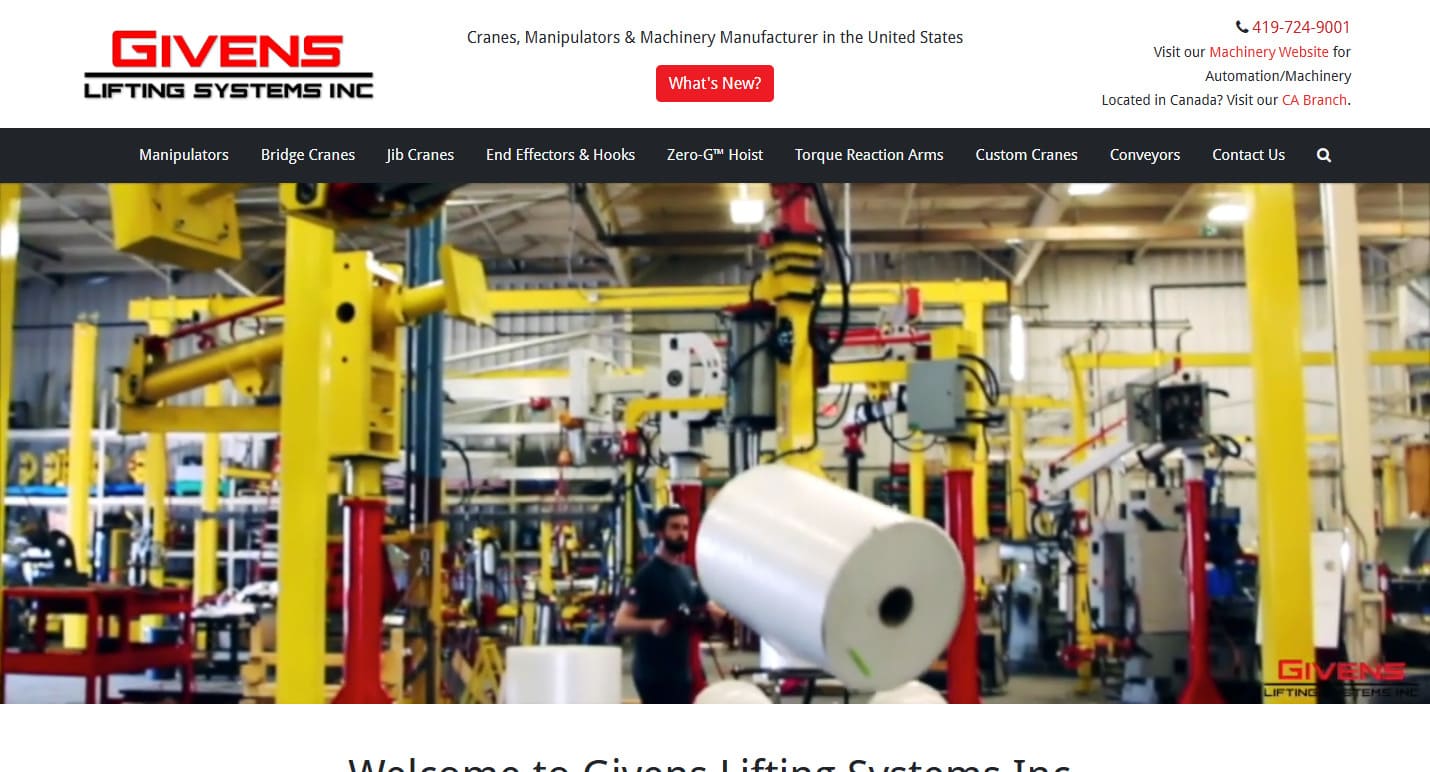

We are Givens Lifting Systems, Inc., a leading company specializing in providing high-quality lifting solutions, with a primary focus on cranes. With our extensive expertise and commitment to innovation, we have established ourselves as a trusted partner for various industries worldwide.

At TC/American Crane Company, we position ourselves as a trusted partner for customers who rely on safe, efficient, and durable lifting solutions. We design and manufacture electric hoists and integrated crane systems that help streamline material handling in demanding environments.

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

More Engine Lift Manufacturers

Although there are three varieties of engine lifts, hydraulic-driven engine lifts are the most popular since they are affordable and intuitive to operate. Whether you are running a professional auto repair shop or working on a car restoration project in your home garage, choosing the right engine hoist (also known as a cherry picker or engine crane) is essential for safe and efficient engine removal and installation. Understanding the different types of engine lifts, their features, weight capacities, and best-use applications can help you make the ideal choice for your automotive or industrial needs.

How an Engine Lift Works

Auto repair shops, DIY mechanics, and industrial maintenance teams depend on engine lifts to provide the lifting force and support needed to safely remove or install engines in vehicles. Changing and repairing an engine is a careful, methodical process that must be performed with the greatest attention to safety, both for the mechanic and for the expensive engine components involved. The correct use of an engine lift or hoist is crucial in preventing injuries and protecting your equipment investment.

- Positioning – Engine lifts consist of several main components: a boom, frame, and two legs with four wheels. The legs and boom extend from the frame, allowing the entire assembly to be easily maneuvered to cradle a car or truck. The legs slide underneath the vehicle while the hoist is positioned directly above the engine. For optimal safety and balance, the engine must be lifted vertically, without twisting or swaying. Modern engines often require an engine leveler with two or four hooks to wrap securely around the engine. The leveler, attached to a bar with chains and hooks at both ends, provides superior stability by connecting to multiple engine points. The top of the leveler is then hooked onto the boom of the engine lift, ensuring a balanced and controlled lift.

- Preparation – Before removing an engine, it is vital to prepare the work area and the vehicle. This includes draining all fluids (oil, coolant, transmission fluid, etc.), disconnecting battery cables, and removing any engine parts or accessories that could interfere with the lifting process, such as the radiator, exhaust manifold, or intake system. Fuel lines must be safely disconnected and depressurized. The engine is then separated from the transmission by removing the bolts that secure it to the engine mounts. Proper preparation is essential for a smooth, safe engine removal with any engine hoist.

- Weight Capacity – Car engines generally weigh between 150 and 800 pounds, while larger truck and commercial vehicle engines can weigh as much as 4,500 pounds or more. Always verify your engine lift’s rated weight capacity, which is clearly printed on the equipment along with detailed operating instructions provided by the manufacturer. Choosing an engine lift with adequate capacity is one of the most important safety and performance considerations.

- Connecting the Engine – Attaching the engine securely to the lift is a critical step. The most common method is bolting the engine lift chain or wire rope to the engine’s cylinder head or block, using designated anchor points. Many modern engines are designed with integrated lifting eyes or brackets for this purpose. For engines lacking such features, engine levelers with heavy-duty straps or chains can be wrapped around the engine to ensure a tight, slip-resistant connection. A secure, balanced attachment prevents the engine from slipping, twisting, or shifting during the lift—especially important for modern vehicles with tight engine bays or engines that must be maneuvered at an angle.

- Raising the Engine – With the engine securely attached, you can begin lifting. Hydraulic engine lifts use a hydraulic cylinder and pump mechanism to generate lifting force, while chain engine lifts employ a manual chain drive. Electric engine lifts utilize an electric motor for effortless lifting. It is essential to operate the lift slowly and steadily, maintaining full control of the engine as it is raised out of the vehicle. Once free, the engine can be safely transported for repairs or installation.

A useful accessory for engine removal is a lift plate, which bolts directly to the engine's intake manifold. Once the lifting plate is in place, the engine lift's hook and chain attach to the plate, providing a solid, centralized lifting point and making the process safer and more efficient.

Types of Engine Lifts: Choosing the Right Solution

The three primary types of engine lifts—chain, hydraulic, and electric—differ in their lifting mechanisms, power sources, and ideal use cases. Understanding the differences will help you select the best engine lifting equipment for your needs, whether you are a professional mechanic, a hobbyist, or an industrial user.

- Hydraulic Engine Lifts – These are the most widely used engine cranes in automotive repair shops and home garages. Hydraulic engine lifts feature three main parts: a robust hydraulic cylinder, adjustable boom, and sturdy legs with caster wheels. The hydraulic cylinder is mounted to the frame and powers the boom up and down. Hydraulic lifts are known for their high lifting capacity, smooth operation, and portability. They are ideal for removing and installing engines in cars, trucks, SUVs, and light-duty vehicles. Many models are foldable for easy storage when not in use, and some offer telescoping booms for extended reach. Their cost-effectiveness and user-friendly design make them the top choice for most automotive applications. When searching for a hydraulic engine hoist, consider features like weight capacity, adjustable boom length, and build quality.

- Chain Engine Lift – Chain engine lifts, sometimes called manual chain hoists or block and tackle hoists, are typically mounted to a fixed structure such as a gantry crane, jib crane, or wall bracket. These lifts operate via a hand-pulled chain, which drives gears and sprockets to multiply lifting force. A built-in brake or ratchet mechanism holds the load securely once lifted. Chain engine hoists are valued for their simplicity, low cost, and reliability, but they have lower lifting capacities compared to hydraulic or electric lifts. They are best suited for lighter engines or for use in settings where portability is less important than stability and cost savings. If you want to learn more about the best applications for chain hoists, ask yourself: Is a manual chain hoist right for my garage or workshop?

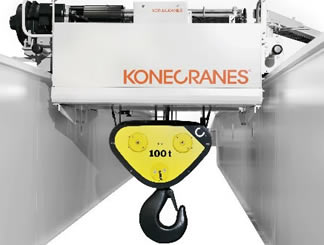

- Electric Engine Lifts – Electric engine lifts are equipped with an electric motor that powers a drum, winding a chain or wire rope to raise and lower the engine. These lifts offer the highest lifting capacities and are often found in factories, warehouses, and industrial environments where heavy engines or components need to be moved efficiently and frequently. Electric engine hoists can be controlled via wired or wireless remotes for precision and safety. However, their larger size and higher cost make them less common in smaller auto shops or home garages. When evaluating electric engine hoists, consider your available power supply, required lifting capacity, and the frequency of engine removal tasks.

Engine Lift Use Cases and Applications

Engine lifts are essential tools in a variety of settings:

- Automotive Repair Shops: Used for engine removal, installation, and replacement in cars, trucks, motorcycles, and specialty vehicles.

- DIY Garages: Enable hobbyists to rebuild or swap engines at home, improving project flexibility and cost savings.

- Industrial Maintenance: Move heavy machinery engines, compressors, generators, and large mechanical assemblies for servicing.

- Manufacturing Facilities: Support assembly lines and heavy equipment maintenance by facilitating safe engine handling.

- Educational Institutions: Automotive training schools use engine lifts for hands-on instruction and engine teardown exercises.

If you need to compare engine lift models for a specific application, ask: What type of engine lift is best for my project, vehicle, or workshop? Explore our in-depth product guides for more details on each lift type.

Engine Lift Benefits: Why Invest in Quality Lifting Equipment?

Investing in a high-quality engine lift provides several key benefits:

- Improved Safety: Proper lifting equipment minimizes the risk of injury from lifting heavy engines manually.

- Efficiency: Streamlines engine removal and installation, reducing labor time and improving workflow.

- Versatility: Many engine lifts are adjustable, allowing use on various vehicles and engine sizes.

- Durability: Heavy-duty steel construction and reinforced joints ensure long-term reliability.

- Precision: Accessories like engine levelers and lift plates provide better control, especially for complex swaps.

- Cost Savings: Investing in the right engine hoist can save money on outsourced labor and prevent costly damage to engines or vehicles.

Ready to choose the best engine lift for your needs? Jump to our engine lift selection checklist or browse our engine lift manufacturer directory for top-rated suppliers.

Key Factors When Choosing an Engine Lift

Before purchasing an engine lift, consider these essential decision factors:

- Weight Capacity: Always select a lift with a rated capacity that exceeds the weight of your heaviest engine. Overloading is dangerous and can damage both the engine and the lift.

- Lift Type: Hydraulic, chain, or electric—match the lift type to your workload, budget, available space, and frequency of use.

- Boom Reach and Height: Ensure the boom extends far enough and high enough to clear your vehicle’s engine bay and accommodate the required lifting height.

- Portability and Storage: Folding or compact models are ideal for home garages or mobile repair businesses.

- Build Quality: Look for reinforced steel construction, quality welds, and durable wheels or casters.

- Accessories: Engine levelers, lift plates, and adjustable booms can enhance versatility and control.

- Ease of Assembly: Some lifts require significant setup; check for clear instructions and support from the manufacturer.

- Warranty and Support: Choose brands that offer robust customer support, replacement parts, and warranty coverage.

Still unsure which engine lift is right for you? Explore our engine lift buying guide or use our RFQ form to request quotes from multiple manufacturers.

Comparing Engine Lift Brands and Manufacturers

To ensure optimal results when purchasing an engine lift, it is important to compare several companies using our comprehensive engine lift manufacturer directory. Each manufacturer’s profile highlights their core areas of expertise, product range (including hydraulic, electric, and manual engine hoists), certifications, and customer reviews. Our directory allows you to:

- Review detailed business profiles to assess manufacturer experience and capabilities

- Preview each engine lift company’s website using our patented previewer tool

- Contact manufacturers directly via built-in forms to request more information or a custom quote

- Submit a single RFQ form to reach multiple engine lift suppliers efficiently

When comparing brands, consider factors like after-sales support, warranty policies, shipping options, and availability of replacement parts. For industrial users, also review compliance with safety standards and any relevant certifications. For more information on how to select a trusted manufacturer, see our guide: Choosing the Best Engine Lift Supplier.

Frequently Asked Questions About Engine Lifts

- What size engine lift do I need? – Calculate the weight of your engine and choose a lift with a higher capacity. Consider the size and reach required for your particular vehicle or engine bay.

- Can I use an engine lift for other heavy lifting tasks? – Yes, many engine hoists are versatile enough for moving transmissions, generators, or heavy shop equipment, provided the load is within the rated capacity.

- What maintenance does an engine lift require? – Regularly inspect hydraulic fluid levels, check for leaks, lubricate moving parts, and verify all connections and fasteners before use.

- How do I safely store my engine lift? – Store in a dry location, keep hydraulic cylinders upright, fold if possible, and periodically check wheels and hardware for wear.

- Where can I buy replacement parts for my engine hoist? – Most reputable manufacturers offer spare parts and service kits. Check their product pages or contact their support teams directly.

Still have questions? Contact leading engine lift manufacturers or explore our engine hoist FAQ section for more details.

Engine Lift Accessories and Upgrades

Enhance the capability and safety of your engine lift with these popular accessories:

- Engine Levelers: Provide multi-point attachment and balance for complex engine removals.

- Lift Plates: Offer secure single-point lifting for engines with suitable intake manifolds.

- Load Slings and Chains: Enable flexible attachments around challenging engine shapes.

- Replacement Hydraulic Jacks: Upgrade or replace worn-out hydraulic units for consistent lifting performance.

- High-Performance Casters: Improve mobility, especially in tight shop spaces.

- Protective Covers: Shield your engine lift from dust, moisture, and shop debris.

For a full list of compatible accessories, see our engine lift parts and upgrades guide.

Conclusion: Find the Best Engine Lift for Your Needs

Choosing the right engine lift is a critical decision for anyone involved in automotive repair, industrial maintenance, or equipment manufacturing. By understanding the types of engine lifts available—hydraulic, chain, and electric—their use cases, and key decision factors, you can select an engine hoist or engine crane that delivers safety, efficiency, and long-term value. Use our manufacturer directory and buying guides to compare top-rated brands, request quotes, and connect with experts who can help you find the perfect solution for your shop or project.

Ready to take the next step? Browse engine lift manufacturers now or request a custom quote for your specific requirements.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches