A winch, essentially a hoist, is a versatile and powerful device widely used across various industries and applications. It serves as a valuable tool for lifting, pulling, and positioning heavy loads with precision. Whether it’s recovering vehicles in off-road situations, supporting construction projects, or aiding marine operations, winches are essential for tasks requiring controlled force and enhanced maneuverability. Read More…

At Spanco, Inc., we take pride in designing and manufacturing high-performance lifting solutions that improve efficiency, safety, and productivity across industrial environments. As a leading producer of electric hoists and overhead crane systems, we bring together decades of engineering expertise and precision craftsmanship to create equipment that supports a wide range of material handling...

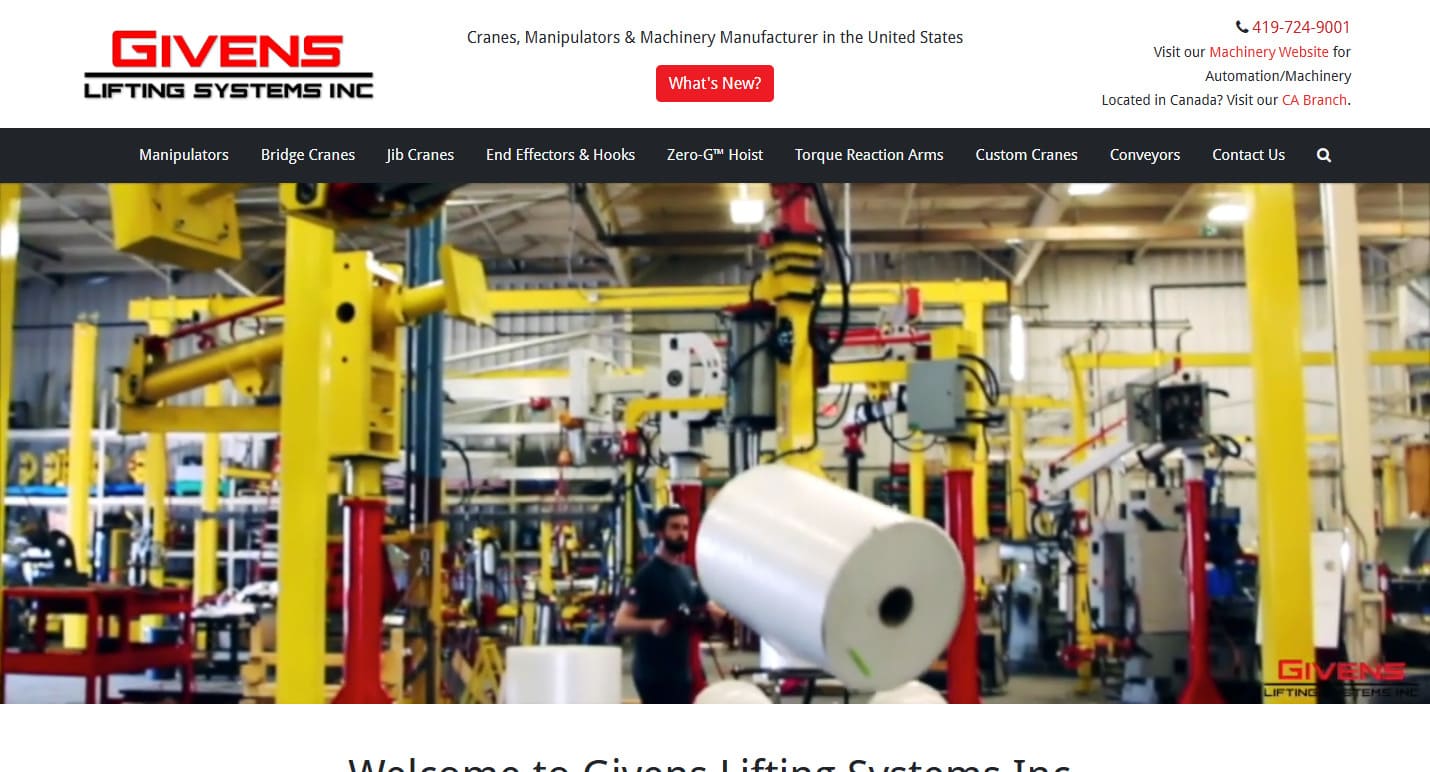

We are Givens Lifting Systems, Inc., a leading company specializing in providing high-quality lifting solutions, with a primary focus on cranes. With our extensive expertise and commitment to innovation, we have established ourselves as a trusted partner for various industries worldwide.

At TC/American Crane Company, we position ourselves as a trusted partner for customers who rely on safe, efficient, and durable lifting solutions. We design and manufacture electric hoists and integrated crane systems that help streamline material handling in demanding environments.

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

More Winch Manufacturers

Components of a Winch

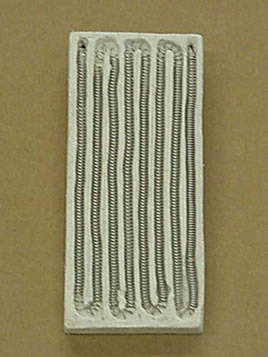

Winches consist of several key components that work in harmony to facilitate their operation. At the core is the drum or spool, where the wire rope or synthetic rope is wound. Power is supplied by an electric, hydraulic, pneumatic, or hand-operated motor, depending on the type of winch. The motor's energy is transmitted through a gearbox, which converts power and increases torque, allowing for greater lifting capacity. A clutch engages or disengages the drum, enabling control over the movement of the load. A brake ensures load stability and prevents unintended movement. The wire rope or synthetic rope serves as the means to transfer force and carry the load, while a control system governs the winch's operation and integrates safety features.

Variations of Winches and Their Specific Applications

Winches come in many variations to cater to specific needs and applications. Standard winches are the most common type, offering reliable pulling power, ease of operation, and versatility across different industries. High-speed winches, meanwhile, prioritize line speed, making them ideal for quick retrieval or positioning of loads. Low-profile winches, on the other hand, are compact and designed to fit into tight spaces, making them suitable for applications with limited mounting options. Additionally, marine winches feature corrosion-resistant materials and waterproof features, ensuring durability and reliable performance in marine environments. Furthermore, industrial winches are heavy-duty variants built to handle demanding industrial applications, with robust construction and high pulling capacities. Each variation of winches offers unique features and benefits, allowing users to choose the most suitable option based on load capacity, line speed requirements, environmental conditions, and specific application needs.

Considerations Regarding Winches

While winches offer immense utility, there are potential considerations to keep in mind. Safety risks during operation, if not handled properly, can lead to accidents or injuries. Additionally, overloading or improper use of winches may result in equipment damage or even catastrophic failure. Regular maintenance and inspection are also crucial to ensure the winch's reliability and longevity. Additionally, the manufacturing and disposal processes of winches can have environmental impacts, necessitating sustainable practices.

Manufacturer Efforts to Address These Considerations

Winch manufacturers actively address these considerations through various measures. Safety features such as automatic load limiters, emergency stop buttons, and fail-safe mechanisms are integrated into winch designs to enhance user safety. Manufacturers also provide comprehensive user training and guidelines to educate operators on proper winch usage and maintenance. Improved maintenance recommendations, including routine inspections and servicing, are additionally provided to ensure the winch operates at its optimal level. Furthermore, manufacturers embrace sustainable manufacturing practices, such as using eco-friendly materials and implementing recycling initiatives to minimize the environmental impact of winch production and disposal. These collective efforts by manufacturers aim to mitigate potential considerations and promote the safe and responsible use of winches.

Benefits of Winches

Winches offer a range of benefits that make them a popular choice in various applications. To begin with, winches provide consistent and reliable power, ensuring consistent performance and lifting capabilities. They are easy to operate, as they can be controlled remotely with the push of a button, offering convenience and eliminating the need for manual labor. Winches are also relatively low maintenance, requiring minimal upkeep and offering long-term reliability. These benefits collectively make winches a popular choice for a wide range of applications, including off-road vehicles, industrial settings, construction projects, and more.

Applications of Winches

Winches find specific applications in various industries and recreational activities. Off-road vehicles benefit from winches for vehicle recovery in challenging terrains. Meanwhile, construction projects rely on winches to lift and position heavy materials, improving efficiency and safety on job sites. In industrial settings, winches aid in material handling, cargo loading and unloading, and moving machinery. Marine vessels also utilize winches for tasks such as anchor handling, sail adjustment, and lifeboat launching. Even in recreational activities like camping and boating, winches find applications in setting up campsites, raising tents or sails, and lifting heavy equipment. The versatility and reliable power of winches make them a valuable tool in these, and other, applications, enhancing productivity and simplifying tasks.

Choosing the Proper Winch Supplier

To ensure you have the most positive outcome when purchasing a winch from a winch supplier, it is important to compare several companies using our directory of winch suppliers. Each winch supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each winch business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple winch companies with the same form.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches